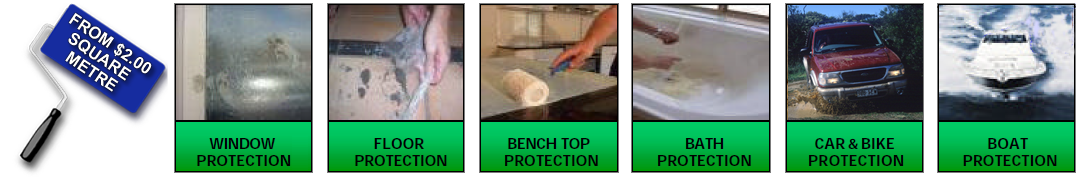

PRODUCT INFORMATIONgoGREEN DIY protective films goGREEN’S Enterprises protective films are DIY water based liquid applied films that are simply rolled onto the applicable surface using the recommended thick nap roller to temporarily protect numerous valuable substrates from damage. goGREEN’S Enterprises protective films ease of application allows it to stand apart from other protection products as you only require a 20mm nap roller and a bucket for application. The products are applied simply with one coat application and dry to a clear tough protective film that will last up to 12 months on the surface*. goGREEN’S protective films will protect the surface from general damage caused by mortar/render, paint, dropped tools, contractor traffic, grinding sparks, stone chips, bug/bat droppings, UV, branches, rubber burn and sand blasting. The dried protective film is extremely tough and will not fall off or bake on and will continue to provide optimum protection until it is removed from the surface. Once the protection is no longer required the protective film easily peels off to remove and unveils a clean damage free surface – there is no need to use harsh chemicals or heavy tools and the product can be disposed of in normal landfill as all of goGREEN’S protective films are 100% bio-degradable. goGREEN Enterprises supply a thorough application manual and DVD when purchasing the product and are available for any technical advice that may be required. Product demonstrations and training can also be provided on request. The outstanding features of goGREEN protective films are:

* Longevity of the protective film is dependent on the surface, conditions, and application thickness in which it is applied – all films must be applied at the minimum application thickness and in accordance to its instructions. Please refer to technical table below. Technical

** The thickness of all products is measured in Microns (µm) which is equivalent to one millionth of a metre or one thousandth of a millimetre.

Application temperatures The desired application temperature for applying the films is between 10 – 25ºC. Applying the products outside these temperatures can affect the films drying and curing times, and performance. Try to avoid applying the product in very humid and frosty conditions or if heavy rain is expected within 24 hours of the films application. Avoid applying in the middle of the day when the temperatures are at their peak. Areas being applied must have sufficient ventilation such as an open window, as this ensures that the films dry and cure at their optimum. If there is no ventilation available you must use fans or lights to increase the drying time. Removal The desired removal temperature of goGREEN protective films is between 10 - 25ºC. Water can be applied to aide release if removing outside those temperatures. Simply spray the dried membrane with water from a hose or spray bottle and leave for a couple of minutes to allow the membrane to soften, and then peel as usual. If the product is applied too thin and removal becomes difficult simply apply water to aide release. A high pressure hose can be used with care. Ensure there are no dried pieces of film are left on any surface The product must be fully cured prior to removal. Disposal Roll the peeled off membrane into a ball and dispose of in normal landfill. All of goGREEN protective films are 100% bio-degradableCuring/Drying Times

Clean up All of goGREEN’S temporary peelable films are water-based and can be simply cleaned using water When not to apply

Warranty The information contained herein is believed to be reliable but no representations, guaranties or warranties of any kind are made as to its accuracy, suitability for particular applications or the results to be obtained there from. The information is based on laboratory work with small-scale equipment and does not necessarily indicate end product performance. Because of the variations in methods, conditions and equipment used commercially in processing these materials, no warranties or guarantees are made as to the suitability of the products for the application disclosed. Full-scale testing and end product performance are the responsibility of the user. The Seller makes no warranties, expressed or implied including but not limited to, the implied warranties of merchantability and fitness for a particular purpose. No returns of merchandise will be accepted without our written consent and inspection. Suggestions and recommendations are made without warranty or guarantee of any kind, the buyer assumes all risk and liability for the results of such use. No claim of any kind shall be greater in amount than the purchase price of the material.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||